I am just about to start putting in the side sound ports. I bind the edges of the sound port to match the instrument purfling, so it is generally black-white-black or black-red-black. I apply the layers to the edge of the sound hole one at a time with cyanoacrylate (CA) glue (more on that later). As preparation I pre-bend the veneers so they will fit in the sound hole.

I used to use a propane torch in a piece of pipe but this produced fumes and was not very controllable. (I burned a hole in a flannel shirt once standing too close to the exaust.) I found these small cartridge heaters that you can buy. They come in various wattages, and are not very expensive. So I bought some, and wired them up to a cord (they do not come with a plug or anything).

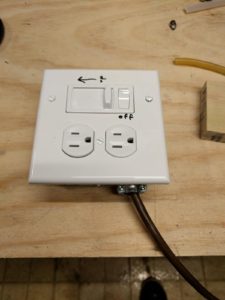

To control the temperature I got a standard household dimmer, like you would have for lights. These are rated for 600 watts, which is plenty. I put this into an electrical box with a controlled outlet.

Plug the cartridge heater in, shove it down a length of pipe, adjust the dimmer to get the heat you want (hot but not scorching) and bend away. Larger pipe for bigger bends, smaller pipe for tight bends.

You end up with a lot of little rings. The thick black ones are for the outside edge of the soundhole binding, which I make thicker.