The end of the uke shape I build has a 5 inch radius curve. This means that the end block on the inside, to which the sides are glued, needs to have a 5 inch radius curve.

To do this I made up a simple jig with a 5 inch radius pivot that clamps to my oscillating drum sander. I just clamp an end-block blank in the jig, rotate it against the sanding drum, and I get a perfect 5 inch radius face every time. (The jig is next to the piviot pin in the photo)

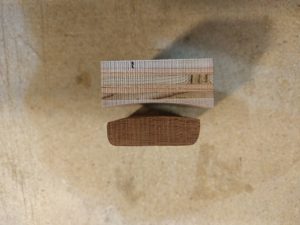

When gluing the sides to this curved end block, one also needs a matching clamping caul with a corresponding 5 inch radius hollow for the outside of the sides. One could manually make a hollow with chisels and/or a sander but here is a much simpler way. Get some auto-body putty (bondo), mix some up (it is a very thick paste), put a blob on a piece of plywood, cover with a piece of wax paper, and press a radiused end block into the bondo. Let it harden, cut off the extra, and you are left with a perfect matching curve.